If you look through a U.S. Standard, for just about any commodity, you will find it includes the applicable U.S. Grades, defect tolerances, defect scoring guidelines and application of tolerances. For example, let’s look at the U.S. Standard for Cucumbers.

If you look at Section: §51.2228 Application of tolerances.

(a) The contents of individual packages in the lot, based on sample inspection, are subject to the following limitations: Provided, That the averages for the entire lot are within the tolerances specified for the grade:

(1) For a tolerance of 10 percent or more, individual packages in any lot shall have not more than one and one-half times the tolerance specified, except that when the package contains 15 specimens or less, individual packages shall have not more than double the tolerance specified; and,

(2) For a tolerance of less than 10 percent, individual packages in any lot shall have not more than double the tolerance specified, except that at least one defective and one off-size specimen may be permitted in any package.

So how do you interpret these guidelines? First, you must know the defect tolerances for cucumbers. For a U.S. No. 1 Cucucumber you are allowed 10% total defects, including 1% decay. The application of tolerances are another way of saying “sample tolerances” or “package tolerances.” In other words, for cucumbers to be U.S. No. 1 they must contain 10% or less of defects, and 1% or less decay…..and there is a limit, or tolerance established for defects in an individual sample or carton.

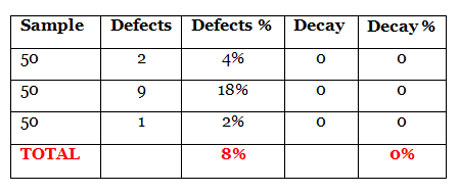

Looking at the definition quoted above, in (1), let’s assume we had more than 15 cucumbers in our carton. We counted out 50 cucumbers for our sample. According to the definition, you would not be allowed more than 1-1/2 times the defect tolerance of 10%, or 15% defects in any sample. While you are running your samples you may encounter the following:

The total defects averages 8%, within the tolerance for defects allowed (10%), but the second sample exceeds the application of tolerances, as no sample is allowed to exceed 1-1/2 times the tolerance, or in the case of cucumbers, no sample is allowed to exceed the total defect tolerance of 15%. Thus, these cucumbers would fail to grade U.S. No. 1.

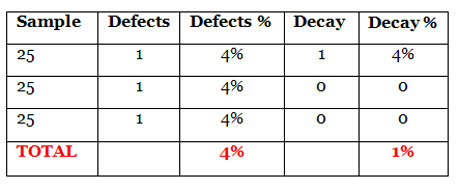

Looking at the scoresheet above, the application for tolerances with a tolerance less than 10%, (2) in the definition will come into play. Using cucumbers as our example, no sample may exceed double the tolerance. The decay tolerance for decay is 1%, which means no sample may exceed double the tolerance or 2% decay. At first glance you may think the cucumbers are out of grade, as the first sample exceeds the tolerance for decay. The first sample has 4% decay, as you found 1 decayed cucumber in your 25 sample.

But look at the last part of the defintion….“except that at least one defective and one off-size specimen may be permitted in any package.” This is statement is found in most U.S. Standards, as they usually allow for at least one defective specimen in a sample, as long as the final totals are within the tolerances allowed. In the example shown above, with the 25 count samples, the cucumbers would still be in grade. The total defects are 5% (4% defect plus 1% decay), you are allowed 10%. The decay averages 1%, and the standard allows for 1% decay. Although one sample did exceed the application of tolerances (4% and the standard allows no more than 2%), only 1 cucumber was decayed, and the standard allows for 1 defective specimen, no matter the percent.

The application of tolerances have many nuances among the variouos products, but the basic rules are all the same. Please feel free to comment if you have any questions about this topic, as this always is the most confusing aspect of understanding the U.S. Standards.

3 Comments on “Application of Tolerances”

Alakazaam-information found, problem solved, tnhaks!

We call this the “one potato rule” in SPI

Thank you!