More and more companies are choosing to create their own “Company Produce Buying Specifications” as a method to improve their quality of produce received, better than U.S. No.1 Grade. These fresh produce specs usually include changes to minimum sizes, uniform size, or increased tolerances for defects, including decay,

The USDA has always provided, with their service, to inspect the produce based on the company specs, when requested, during their official inspections. The USDA Certificate will note this on their certificate, not making any statement as to whether the product meets the U.S. Grade or if it fails to meet the U.S. Grade, but the certificate will state that the inspection meets of fails meet the Company Specification, and that the inspection was based upon the Company Specification at the Applicant’s request.

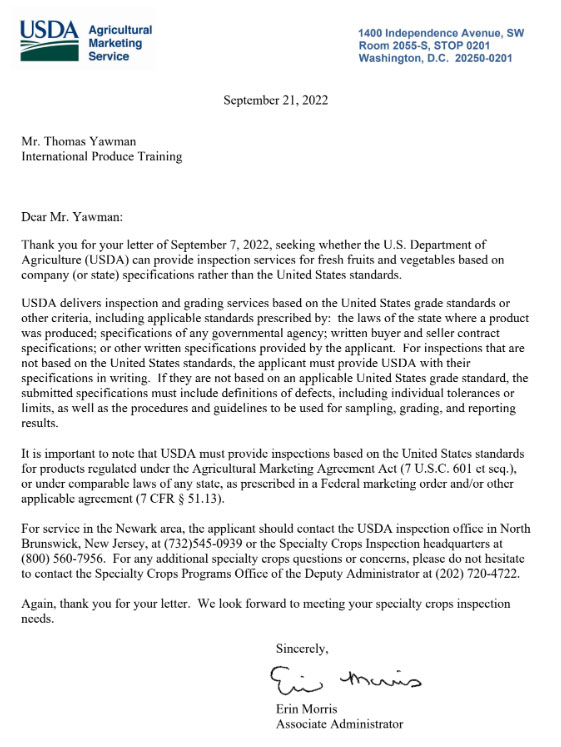

Unfortunately a few USDA offices have refused to inspect on the basis of a company’s produce specification, causing some confusion. I reached out to the USDA asking if this policy was in effect, and received the following reply:

This is good news, as many contracts between buyers and sellers are based upon the company specifications. Part of the answer did surprise me a bit, as the USDA will alter sampling procedures if such procedure is in writing and provided to the USDA inspector prior to the inspection:

“If they are not based on an applicable United States grade standard, the submitted specifications must include definitions of defects, including individual tolerances or limits, as well as the procedures and guidelines to be used for sampling, grading, and reporting

results.”

A few examples came to mind when I read this. For example, when the USDA inspector encounters an internal defect on watermelons the inspector may cut all 100 melons sampled to look for the internal defects. A company’s specification could include a cutting procedure for watermelons, setting the number of cut melons to not exceed 50 melons, or even 25 melons, and to base the percentage of internal defects on those cut melons. Another way a company could eliminate some waste or loss during an inspection is to limit the number of samples the USDA inspects to a set number of 4 or 5, instead of the USDA destroying 10 or more cartons of lettuce, potatoes, or citrus during their inspections. Something to consider for sure.

No Comments on “Company Specifications”